Ensuring consistent product quality is vital in high-volume industrial production. Traditional manual inspections are not only time-consuming but also prone to human error, leading to increased waste and production downtime. To address this challenge, an AI-powered software solution was introduced to automate quality control using intelligent fault detection, image segmentation, and color analysis.

Problem Statement

In fast-paced industrial environments, maintaining consistent quality across thousands of units is a daunting task. Manual inspection methods often suffer from fatigue-induced errors, inconsistent judgment, and inefficiencies that hinder throughput. Manufacturers needed an advanced, real-time, automated inspection system that could detect faults, segment images, and ensure color accuracy all while integrating seamlessly into existing infrastructure.

Solution

An AI-powered software system was developed to transform conventional camera systems into intelligent quality control units. The system is designed to detect faults, isolate objects through segmentation, and ensure colour consistency, enabling precise and automated inspection.

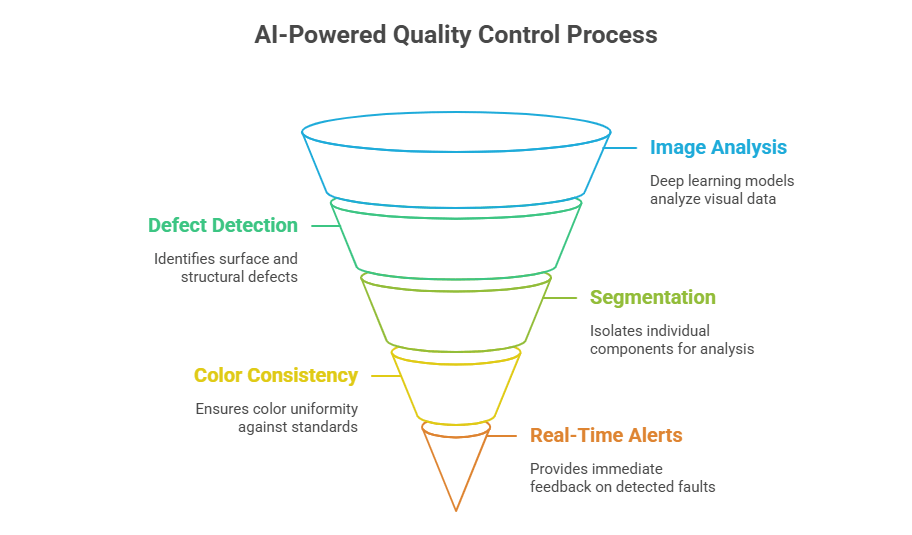

Intelligent Image and Video Analysis

- The solution analyzes real-time image and video feeds from existing production line cameras.

- Through deep learning models trained on large datasets, it detects surface-level and structural defects with high precision.

- It segments individual components from the visuals and assesses their size, shape, and color properties.

Colour Detection and Image Segmentation

- Advanced segmentation techniques enable the software to isolate and analyze individual product units or components.

- Colour detection algorithms compare product colours against predefined standards to ensure uniformity, even detecting subtle colour mismatches.

Real-Time Fault Detection and Feedback

- The software provides real-time alerts for detected faults such as scratches, dents, or discoloration.

- This allows for immediate corrective actions on the production line, minimizing waste and reducing rework costs.

Data Insights and Reporting

- Collected data is transformed into insightful reports, helping manufacturers track defect trends, quality KPIs, and root causes.

- These insights allow for proactive improvements in manufacturing processes.

Benefits

- Accuracy: High precision in detecting minute faults and inconsistencies.

- Efficiency: Significantly faster than manual inspection, enabling higher throughput.

- Waste Reduction: Early detection of defects reduces rework and material waste.

- Real-Time Alerts: Immediate feedback helps operators take swift corrective action.

- Data-Driven Decisions: Actionable insights drive long-term quality improvements.

- Labor Optimization: Reduces the need for repetitive human inspection tasks.

Conclusion

AI-powered quality control is transforming how industries monitor product integrity. By automating the inspection process through fault detection, image segmentation, and color analysis, manufacturers can eliminate human error, reduce operational costs, and ensure consistent product quality. The system is scalable, integrates with existing hardware, and is designed to evolve with future innovations making it a cornerstone for modern industrial automation.

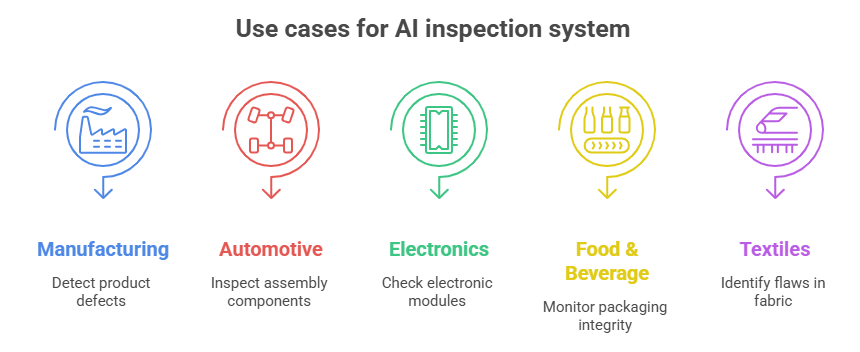

Similar Use Cases / Applications

- Manufacturing: Detect structural and cosmetic product defects.

- Automotive: Inspect body parts, interiors, and assembly components.

- Electronics: Check PCBs and electronic modules for damage or misalignment.

- Food & Beverage: Monitor consistency, packaging integrity, and visual quality.

- Textiles: Identify flaws in fabric weaves and ensure colour uniformity.