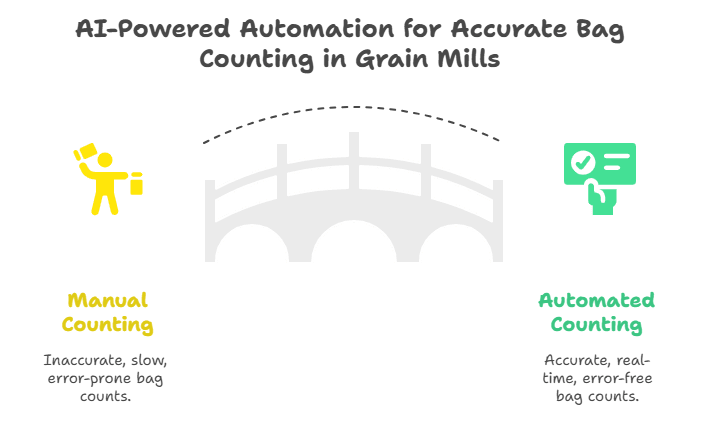

Accurate inventory management is critical for mills handling large volumes of rice, wheat, and other grains. Traditionally, counting the number of bags being loaded and unloaded from trucks has been a manual process, prone to errors and inefficiencies. With the high volume of bags being moved daily, the need for an automated, real-time counting system became essential to ensure accuracy and improve operational efficiency.

Problem Statement

Overcoming Manual Counting Challenges in High-Volume Grain Handling. The mill faced significant challenges in accurately counting the number of bags being transferred between trucks and storage areas (godowns). Relying on manual counting methods not only increased the likelihood of human error but also slowed down the unloading process. This led to discrepancies in inventory records and potential losses. The need for an automated solution that could provide real-time, accurate counts without interrupting the workflow was evident.

Solution

- Solution Implementation:

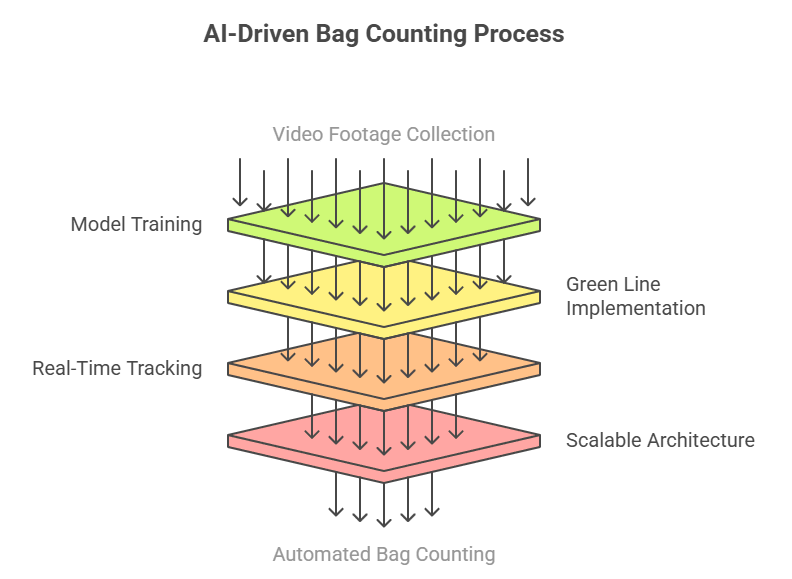

- Developed a sophisticated computer vision solution, leveraging AI and machine learning to automate the bag counting process.

- The system utilized strategically placed cameras to monitor the loading and unloading of bags from trucks.

- Model Training and Video Processing:

- Began with collecting and labeling sample video footage to train the model.

- Introduced a virtual "green line" within the video feed that acted as a counting threshold during the unloading process.

- As each bag crossed this line, the system automatically registered and counted it as being transferred to the godown.

- Real-Time Bag Tracking:

- Utilized deep learning algorithms trained to recognize and track the movement of individual bags in real-time.

- The model was continuously refined to improve accuracy in challenging conditions, such as varying lighting, overlapping objects, and different bag sizes.

- Scalable and Future-Proof Architecture:

- Integrated a scalable architecture that allows for the addition of new features, such as automated alerts for discrepancies or integration with inventory management systems.

- Ensures the system can evolve with the mill's operational needs and technological advancements.

Conclusion

Similar Use Cases

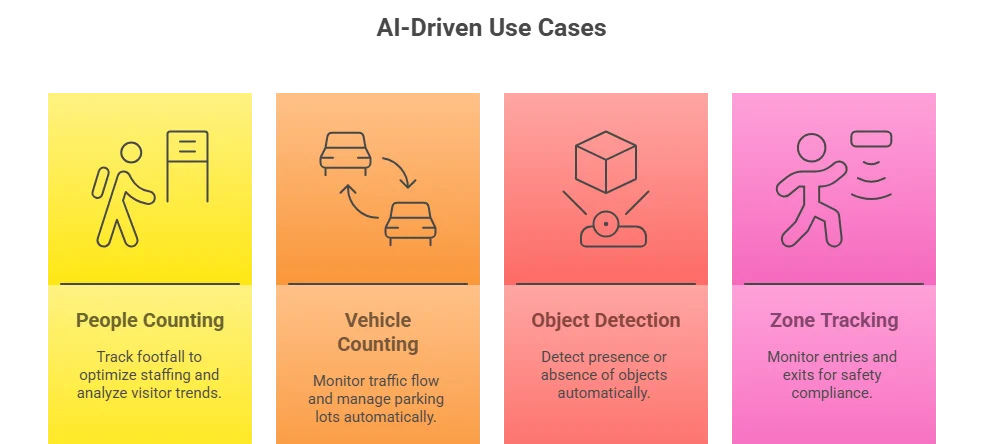

While our advanced solutions like automated bag counting in industrial settings showcase the power of AI, we also help businesses solve simpler yet impactful problems using the same core technology. Here are a few examples of straightforward AI-driven use cases we can implement quickly and cost-effectively:

While our advanced solutions like automated bag counting in industrial settings showcase the power of AI, we also help businesses solve simpler yet impactful problems using the same core technology. Here are a few examples of straightforward AI-driven use cases we can implement quickly and cost-effectively:

- People Counting: Track footfall in retail stores, malls, offices, and events to optimize staffing, improve customer experience, and analyze visitor trends.

- Vehicle Counting: Monitor traffic flow, analyze congestion, or manage parking lots by automatically counting cars, bikes, or trucks using CCTV or IP camera feeds.

- Object Presence Detection: Automatically detect the presence or absence of objects (like pallets, packages, or containers) on shelves, conveyor belts, or loading docks.

- Zone Entry/Exit Tracking: Monitor when people or vehicles enter or leave specific zones, helping with safety compliance and real-time occupancy tracking.