Manually counting pipes especially in industrial, storage, or construction settings—is not only time-consuming but also prone to human error, especially when pipes are stacked together or look identical. Often, workers risk counting the same pipe multiple times or skipping some altogether. This project introduces an AI-powered solution that leverages computer vision to automatically detect and count pipes in an image.

Problem Statement

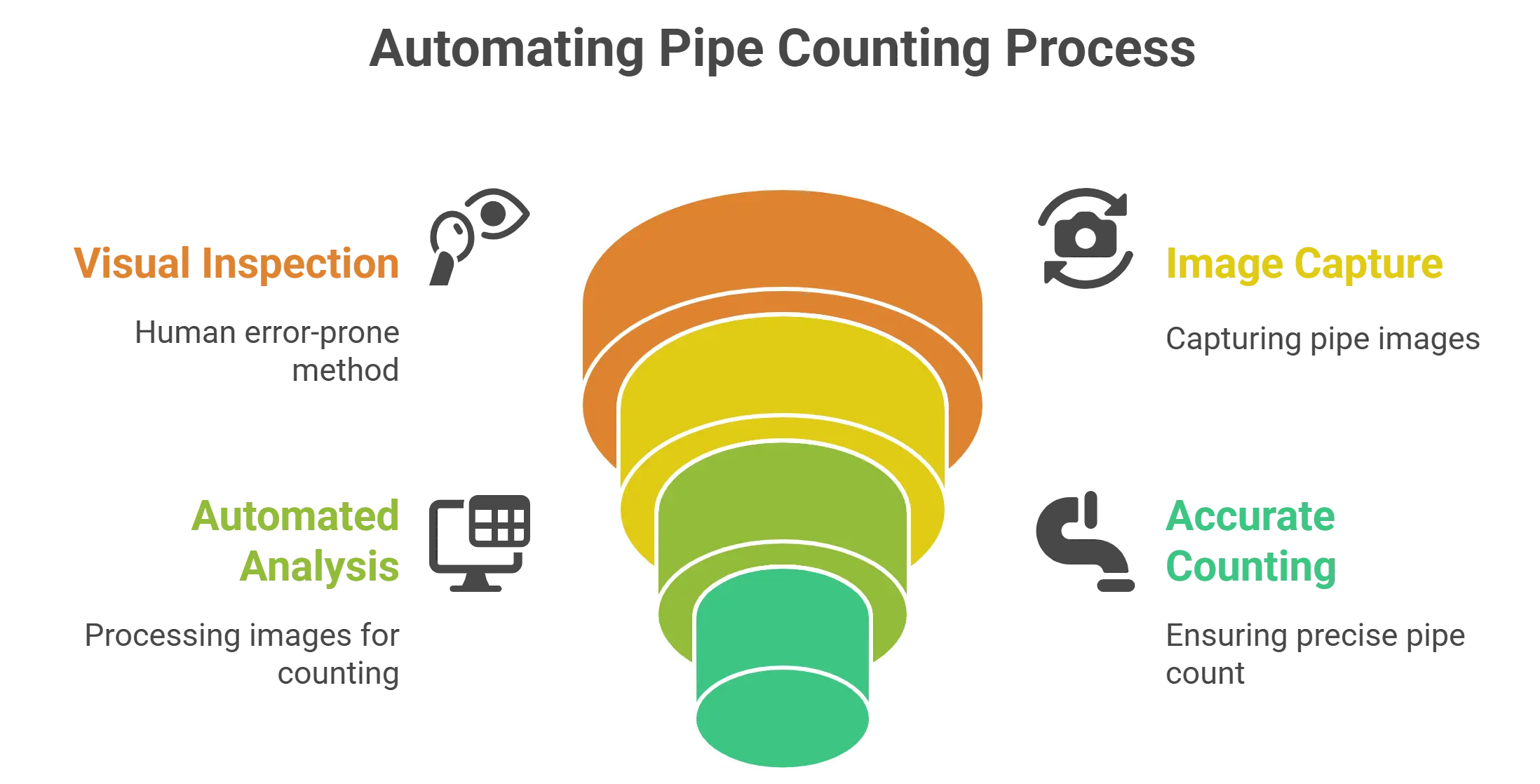

In industrial and warehouse settings, operators are often required to manually count large numbers of pipes based on visual inspection. This process is repetitive, inefficient, and highly susceptible to human error—especially when pipes are stacked closely or partially occluded. This project was designed to automate the pipe counting process from a single image, ensuring accuracy and traceability in inventory management, dispatch verification, and on-site reporting.

Why This Solution Matters

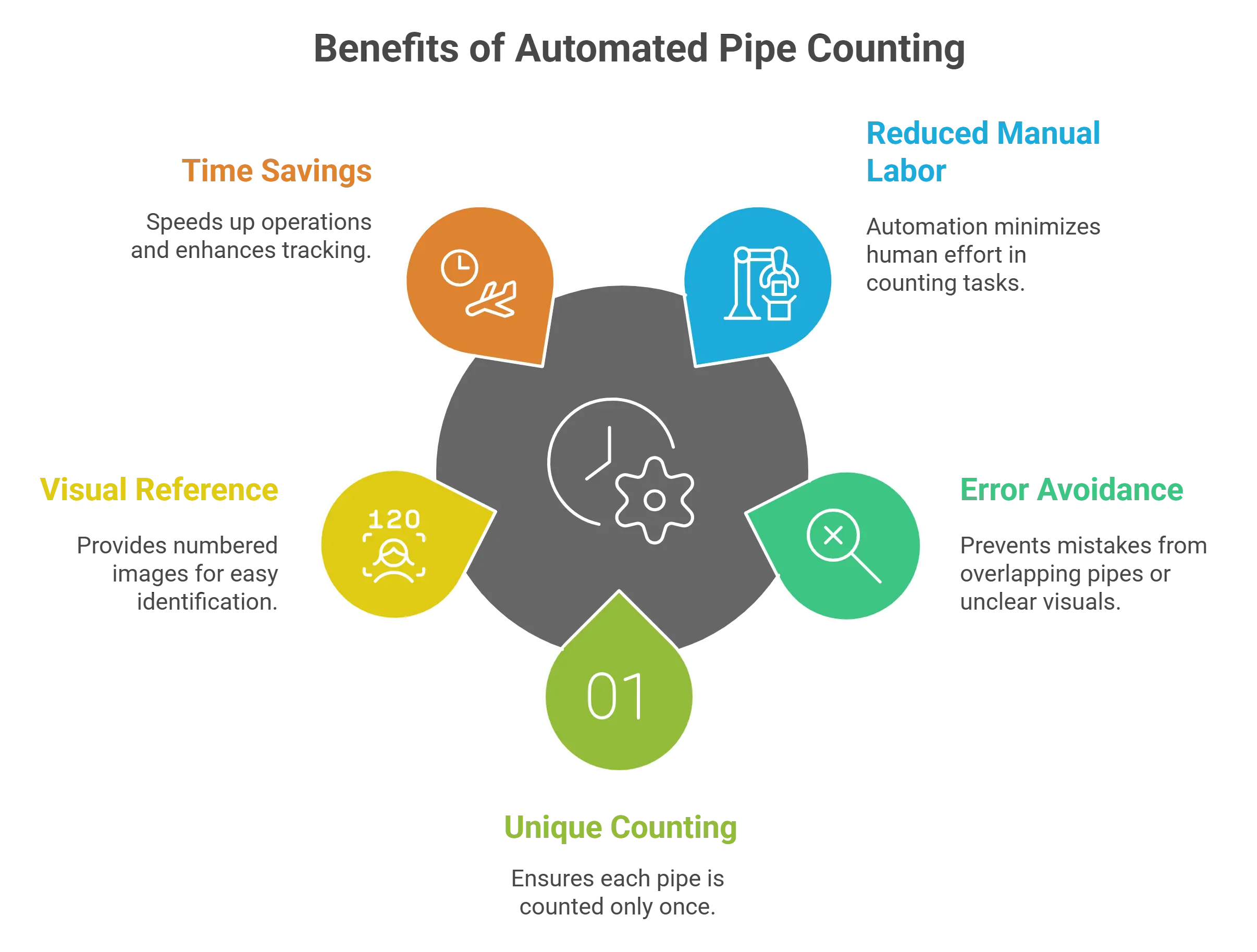

- Reduces manual labour in counting tasks

- Avoids human errors caused by overlapping pipes or unclear visuals

- Ensures that each pipe is counted only once

- Provides a visual reference with numbers overlaid on the image

- Saves time and improves tracking in daily operations

Solution Implementation

- Intelligent Visual Inspection:

- Developed a sophisticated computer vision solution, leveraging AI and machine learning to automate the pipe counting process.

- The system processes a single image and outputs a version with unique numbers marked on each detected pipe face.

- Model Training and Data Preparation:

- Curated a diverse dataset by collecting sample images from online sources, industrial environments, and video extractions.

- Images were carefully annotated to identify visible pipe ends under different conditions (angles, lighting, background clutter).

- Custom object detection model was trained to recognize and differentiate pipe faces with high accuracy.

- Image Processing and Counting Logic:

- Accept user-provided images and detect and localize each visible pipe face.

- Assign a unique index number to each detection.

- Visually annotate the input image with bounding regions and numeric labels.

- Scalable and Future-Proof Architecture:

- Built with a modular and scalable architecture for future enhancements.

- Integration capabilities with mobile or web-based platforms for field deployment.

- API endpoints for integration with inventory or logistics systems.

- Extension support for video-based real-time pipe tracking and batch-wise reporting.

Conclusion

Similar Use Cases

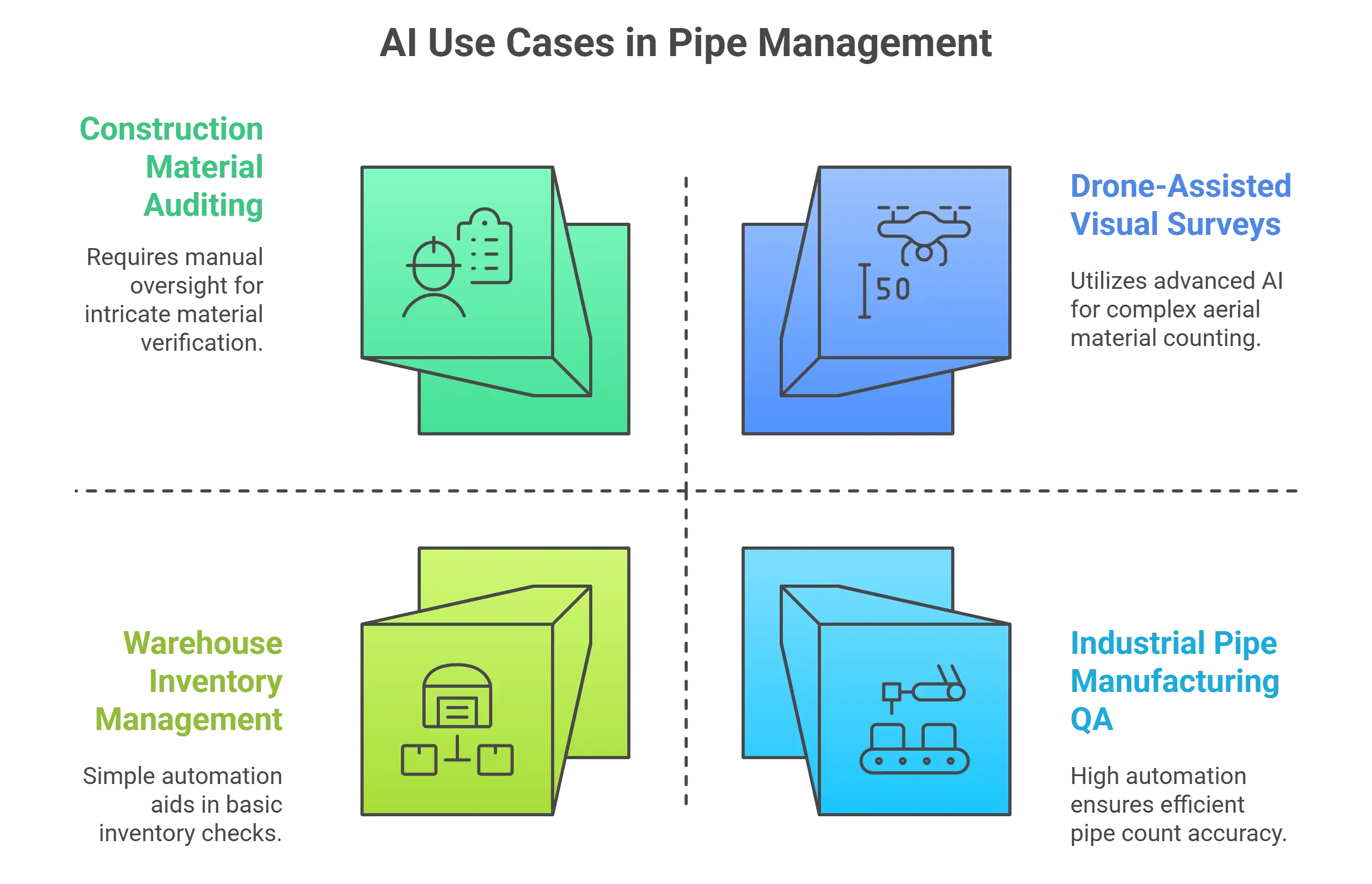

While advanced computer vision models can significantly improve industrial counting tasks, AI Alpha Tech also implements simpler, high-impact solutions that help automate visual inspection with minimal setup and faster deployment.

While advanced computer vision models can significantly improve industrial counting tasks, AI Alpha Tech also implements simpler, high-impact solutions that help automate visual inspection with minimal setup and faster deployment.Here are a few similar use cases we often deliver:

- Warehouse Inventory Management: Automating quantity checks before shipment or restocking cycles using basic object detection.

- Construction Material Auditing: Verifying on-site material delivery or tracking daily usage through image-based counting.

- Industrial Pipe Manufacturing QA: Ensuring correct pipe counts before packaging or loading using automated visual inspection.

- Scrap Yard Monitoring: Automating the categorization and counting of discarded pipe pieces through computer vision.

- Drone-Assisted Visual Surveys: Counting materials in open yards or rooftops from aerial images using AI-powered detection.

- Assembly Line Quality Control: Real-time counting and verification of products moving through production lines.